|

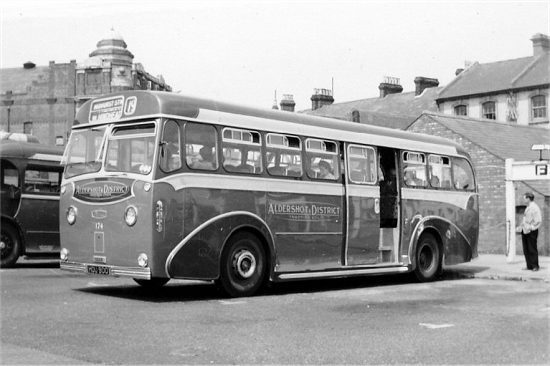

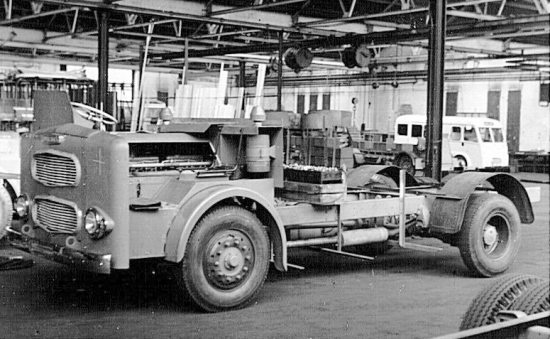

1950 was a significant year in my life. In 1948, at Chichester High School, I had passed the Oxford School Certificate, and in 1950 the London Higher School Certificate.. Many pupils would leave after taking the School Certificate, whilst those who stayed on would specialise in a limited number of related subjects. I took engineering which involved maths, physics, engineering drawing, applied maths and practical applied maths. Most exams were taken at school, but practical applied maths meant a day out to London University. From my exam results I could have probably gone on to study engineering at university, but I chose to seek an engineering apprenticeship, preferably with a commercial vehicle manufacturer. Earlier in 1950, I had an interview at Dennis's and I was shown round their works by an apprentice. In the paint shop was an East Kent Falcon, almost certainly one of the final batch of five. I wonder, was it KFN 584? There was a one in five chance that it was. This is the one owned now by Norman Hamshere, which I have driven many times. In August 1950 I had found lodgings with an apprentice and his mother in Send. He was a fitting shop apprentice working at that time in the engine test department whereas I was an engineering apprentice and would spend time in almost every department starting in the machine shop. In the dinner hours he would show me round the assembly shops and road test. This was a particularly interesting time as two axled single decker buses could now be built to the new size of 30 feet long by 8 feet wide (previously 27 feet 6 inches long by 7 feet 6 inches wide) and double decker buses could now be built to 27 feet long by 8 feet wide (previously 24 feet 6 inches long by 7 feet 6 inches wide) Also at this time, like AEC, Leyland and others, Dennis were developing an under floor engined single decker. I saw three Dominant chassis on the line. One of them, which became HOU 900, had the horizontal version of the established "0.6" 7.58 litre engine with a Hobbs Semi Automatic gearbox. Another was an export model, which became the demonstrator, having a modified horizontal "0.6" with a Rootes blower, boosting the output to 130 B.H.P. through a Hobbs gearbox and a two speed rear axle. The third chassis was for export, but it probably never ran. It was exhibited in chassis form at that years Commercial Motor Show. One evening, a few weeks later, the vehicles to be exhibited at the Commercial Motor Show were displayed in the Road Test Shop. HOU 900 and the demonstrator now had Strachans bodies, as did a 30 feet by 8 feet "J10" Lancet for Aldershot & District.

During my apprenticeship I moved around various areas of the machine shops, centre lathes, capstans, autos, mills and grinders. Unusually, I did not go into the tool room, but instead I went into the millwrights, frequently using their centre lathe as the regular turner was off sick. In the fitting shops I spent time on the chassis assembly line and the lawn mower section. At that time, Dennis were still using their own single cylinder engine, building six a week. In the laboratory I was taught to analyse steel samples to confirm such things as carbon content. While there I was able to see plating and heat treatment being carried out in adjacent workshops. In the drawing office much time was spent recording modifications being made to chassis frame drilling drawings, as at that time many Pax chassis were being fitted with a revised brake servo which meant deleting some holes previously needed and adding new holes for the new unit. One task which I felt was rather futile was attempting to draw brake fluid pipes which could bend in all directions. All that was really needed was a record of length, diameter and the end flares. On the line the fitters bent the pipes in situ, and if a spare was sent out it would be straight and strapped to a length of wood. Apart from meeting the girl who has now been my wife for over 55 years, my time in the planning office was spent issuing prints of new drawings to the drawing print stores and any other area where they may be needed, and assisting with the preparation of planning sheets showing the sequence in which components should be machined in a logical and economic manner and deciding what, if any, jigs or fixtures needed to be produced to ensure consistent and accurate results.

My first job was in the development section of a large company. The department consisted of a manager and three assistants. The work could be interesting, but when I learnt that Dennis were offering me more than the manager was being paid, I left after five weeks and returned as a draughtsman.

A second job related to front entrance Lolines for Middlesbrough. For some reason they insisted on a different layout of the stairs to the top deck, and as a result the linkage from the clutch pedal to the operating shaft at the gearbox needed to be modified. The resulting fabricated bracket which replaced a cover plate on the bell housing was such that it had to be mounted on a fairly simple jig whilst being machined on a jig borer in the tool room. The quantity needed did not justify making a jig which would have made it possible to do the job in the machine shops. Glenton Tours had long favoured Dennis Lancet and Lancet Underfloor coaches. However the gearchange linkage on their earliest LU4's was not satisfactory. Their LU2's had the horizontal "06" engine and the long established "O" type 5 speed overdrive box and I don't know that any operator had a problem with the gearchange linkage on those chassis. Basically the 8 litre engine of the LU4 was a little more than an "06" bored out from 105 to 108mm diameter, the big difference being the use of a Meadows gearbox. From the gear lever to the gearbox required several sections linked with universal joints giving a rotary movement as well as fore and aft travel. By eliminating the offsetting of connections between sections of the linkage to arrive at a basic sliding and rotating motion, it was possible to design a satisfactory solution. A further requirement on this order was the fitting of an exhaust brake, a device which would give a degree of retardation with a light application of the foot-brake before the brakes came on. With the engine exhaust manifold lying quite low it was difficult not to fall foul of the minimum ground clearance requirement. Fortunately that clearance only applied over a certain minimum distance from the front and the installation was accepted.

|

Not only was I fortunate to finish my

five years in the road test, I was then 21 years old and had renewed my

driving licence since my birthday. As a result, in 1955, I held the equivalent

of a full H.G.V. licence. I spent a week going as passenger on several first

test runs with Bill Sadler, who must have had nerves of steel as on several

trips I was allowed to drive the return leg. One day, the charge hand, Stan

Comber, took me out on a Paxit chassis and told me to drive along the A3

and turn up to Puttenham where he stopped me on the hill before returning

to the works via the A31 and A3. Much to my surprise, I was then allowed

out unaccompanied and often Charley Hazel (the second test driver) and I

would take two chassis without test weights on a short run to check that

any rectifications or adjustments were satisfactory. On one run, I was given

a Max6 and told to follow a Jubilant six wheeler on its first test. Because

of the initial running in of the Jubilant’s double-drive rear bogie,

they took the A3 towards London as far as the “AA” roundabout

before returning past the works for the climb up to the Hogs Back. Occasionally

a Pax with Perkins P6 would have a Borg and Beck clutch and Moss five speed

gearbox, whereas most would have a Dennis clutch and four speed crash gearbox.

Even F12 fire engines with Rolls B80 engines had the Dennis clutch and four

speed crash box! When returning down the bypass to turn in at the North

Gate, the rule was to change down to 3rd gear at 17 m.p.h. with a Pax, but

at 35 m.p.h. with an F12. Heavier vehicles with “04” or “06”

engines had the Dennis twin plate clutch and five speed overdrive gearbox.

Not only was I fortunate to finish my

five years in the road test, I was then 21 years old and had renewed my

driving licence since my birthday. As a result, in 1955, I held the equivalent

of a full H.G.V. licence. I spent a week going as passenger on several first

test runs with Bill Sadler, who must have had nerves of steel as on several

trips I was allowed to drive the return leg. One day, the charge hand, Stan

Comber, took me out on a Paxit chassis and told me to drive along the A3

and turn up to Puttenham where he stopped me on the hill before returning

to the works via the A31 and A3. Much to my surprise, I was then allowed

out unaccompanied and often Charley Hazel (the second test driver) and I

would take two chassis without test weights on a short run to check that

any rectifications or adjustments were satisfactory. On one run, I was given

a Max6 and told to follow a Jubilant six wheeler on its first test. Because

of the initial running in of the Jubilant’s double-drive rear bogie,

they took the A3 towards London as far as the “AA” roundabout

before returning past the works for the climb up to the Hogs Back. Occasionally

a Pax with Perkins P6 would have a Borg and Beck clutch and Moss five speed

gearbox, whereas most would have a Dennis clutch and four speed crash gearbox.

Even F12 fire engines with Rolls B80 engines had the Dennis clutch and four

speed crash box! When returning down the bypass to turn in at the North

Gate, the rule was to change down to 3rd gear at 17 m.p.h. with a Pax, but

at 35 m.p.h. with an F12. Heavier vehicles with “04” or “06”

engines had the Dennis twin plate clutch and five speed overdrive gearbox.

Apart

from the project drawing office, the main drawing office was in four sections,

Fire Engines, Municipal, Engine and Gearbox and General. I became part of

the General section where the work largely involved drawing up and detailing

schedules whereby an established design could be adapted to meet customer's

specific requirements. In the sixteen months I was there, three particular

tasks come to mind. A customer ordered a Condor tractor unit with a Gardner

4LW engine and a Meadows gearbox. His special requirement was that a spare

wheel would be carried vertically behind the cab and that it should be possible

for the driver to load the spare wheel into position unaided. The result

was a hinged ramp which also served as a clamp for the wheel. I can only

imagine they had some very strong drivers and that health and safety was

not yet invented.

Apart

from the project drawing office, the main drawing office was in four sections,

Fire Engines, Municipal, Engine and Gearbox and General. I became part of

the General section where the work largely involved drawing up and detailing

schedules whereby an established design could be adapted to meet customer's

specific requirements. In the sixteen months I was there, three particular

tasks come to mind. A customer ordered a Condor tractor unit with a Gardner

4LW engine and a Meadows gearbox. His special requirement was that a spare

wheel would be carried vertically behind the cab and that it should be possible

for the driver to load the spare wheel into position unaided. The result

was a hinged ramp which also served as a clamp for the wheel. I can only

imagine they had some very strong drivers and that health and safety was

not yet invented.